Polyurethane (PU) IsoFoam®

The polyurethane IsoFoam® system provides high thermal stability with its low thermal conductivity by acting like an insulator. Similarly IsoFoam® is electrically non-conductive, x-ray translucent, and appropriate for use in operating rooms and magnetic resonance imaging (MRI) machines. The unique chemical stability of this IsoFoam® will not harden over time.

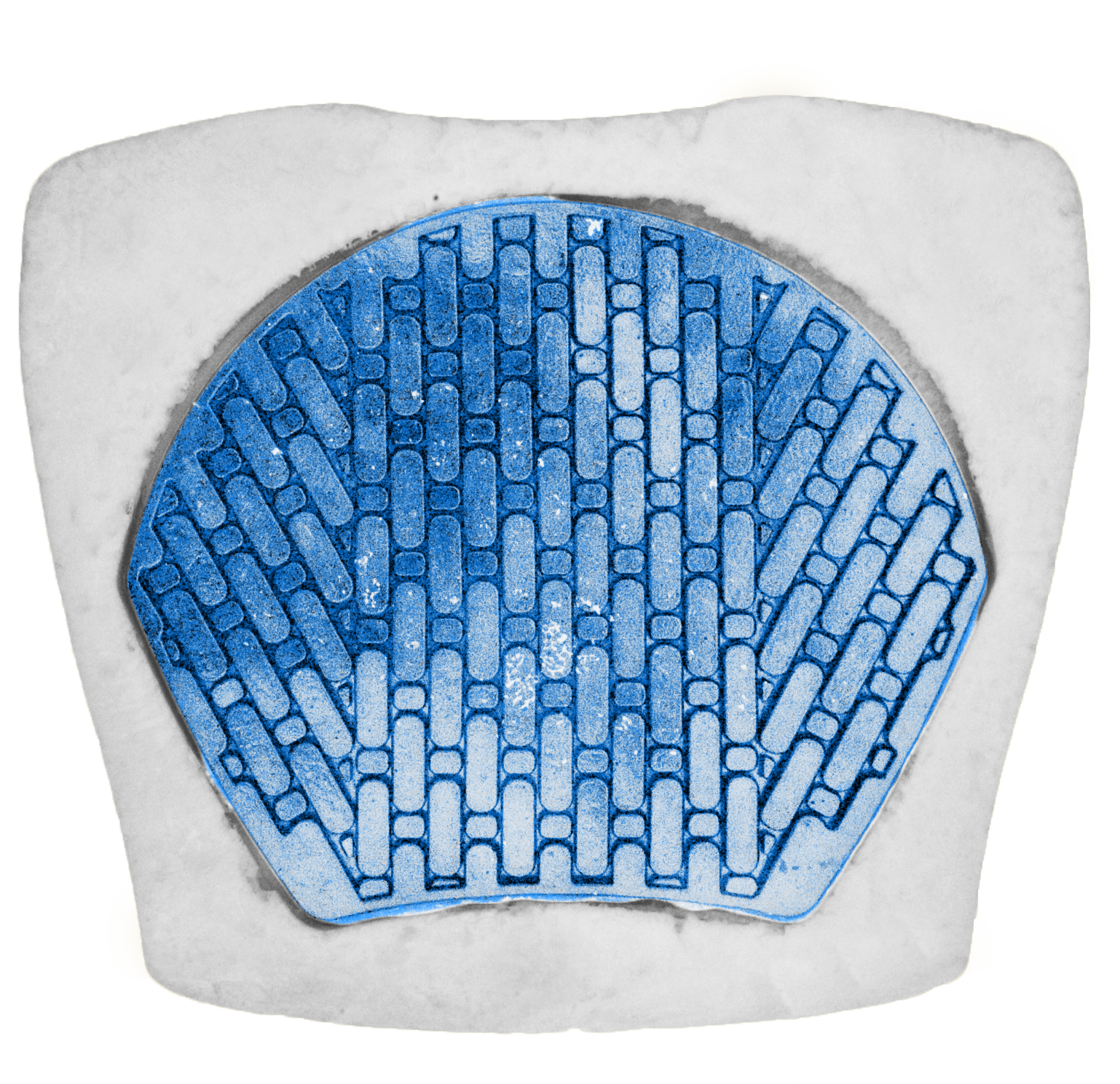

PU IsoFoam® can be molded into various shapes or be used as filler inside of cushions. It can be manufactured to a wide scale of densities and IFDs (Indentation Force Deflections) from densities of 2 to 50 lb/ft^3 and indentation force deflections (IFD) of 4 to 50. The resiliency of IsoFoam® can also be modified to meet performance criteria.

IsoFoam® can be customized to almost any color including but not limited to white, cream, black, blue, red, yellow, and even glow in the dark!*

*Note: color availability is product dependent

IsoFoam® can be formulated to be temperature resistant, flame retardant, chemical resistant, oil and grease resistant, UV resistant, anti-bacterial, anti-microbial, and thermally insulating.

A flexible polyurethane foam that provides the ultimate pressure support and protection where you need it most. The molecular structure provides shock absorption, flexibility, elasticity and comfort by optimizing the achievable stress and tensile properties within foam.

PU IsoFoam® has mainly open cells, formed by gas bubbles that have popped. Air can pass through the foam easily, resulting in a soft, resilient, flexible material. Pittsburgh Plastic Manufacturing’s PU IsoFoam® is a cross-linked system that maintains its integrity while being stretched or compressed in any direction. IsoFoam® can support a large amount of weight (load) and remain soft and flexible over a long period of time. The unique cross-link structure provides high elasticity with high tensile strength.

Its exceptional soft cushioning properties allow for shear force reduction to the user’s skin and body.

A flexible polyurethane foam that provides the ultimate pressure support and protection where you need it most. The molecular structure provides shock absorption, flexibility, elasticity and comfort by optimizing the achievable stress and tensile properties within foam.

PU IsoFoam® has mainly open cells, formed by gas bubbles that have popped. Air can pass through the foam easily, resulting in a soft, resilient, flexible material. Pittsburgh Plastic Manufacturing’s PU IsoFoam® is a cross-linked system that maintains its integrity while being stretched or compressed in any direction. IsoFoam® can support a large amount of weight (load) and remain soft and flexible over a long period of time. The unique cross-link structure provides high elasticity with high tensile strength.

Its exceptional soft cushioning properties allow for shear force reduction to the user’s skin and body.

The polyurethane IsoFoam® system provides high thermal stability with its low thermal conductivity by acting like an insulator. Similarly IsoFoam® is electrically non-conductive, x-ray translucent, and appropriate for use in operating rooms and magnetic resonance imaging (MRI) machines. The unique chemical stability of this IsoFoam® will not harden over time.

PU IsoFoam® can be molded into various shapes or be used as filler inside of cushions. It can be manufactured to a wide scale of densities and IFDs (Indentation Force Deflections) from densities of 2 to 50 lb/ft^3 and indentation force deflections (IFD) of 4 to 50. The resiliency of IsoFoam® can also be modified to meet performance criteria.

IsoFoam® can be customized to almost any color including but not limited to white, cream, black, blue, red, yellow, and even glow in the dark!*

*Note: color availability is product dependent

IsoFoam® can be formulated to be temperature resistant, flame retardant, chemical resistant, oil and grease resistant, UV resistant, anti-bacterial, anti-microbial, and thermally insulating.

A flexible polyurethane foam that provides the ultimate pressure support and protection where you need it most. The molecular structure provides shock absorption, flexibility, elasticity and comfort by optimizing the achievable stress and tensile properties within foam.

PU IsoFoam® has mainly open cells, formed by gas bubbles that have popped. Air can pass through the foam easily, resulting in a soft, resilient, flexible material. Pittsburgh Plastic Manufacturing’s PU IsoFoam® is a cross-linked system that maintains its integrity while being stretched or compressed in any direction. IsoFoam® can support a large amount of weight (load) and remain soft and flexible over a long period of time. The unique cross-link structure provides high elasticity with high tensile strength.

Its exceptional soft cushioning properties allow for shear force reduction to the user’s skin and body.

Memory IsoFoam®: Visco-elastic or memory IsoFoam® is the paramount foam for comfort to the body. This slow recovery IsoFoam® can eliminate pressure points by molding to all contours of your body.

As this IsoFoam® compresses, its counterforce does not increase drastically allowing for continuous pressure distribution. Users have remarked by stating that this IsoFoam® gives them a floating sensation when sitting or lying on top of it.

For the medical industry, it is the first choice for positioning pads, wheelchair seat cushions, and bedding. The industry has seen success with this material in pillow and furniture applications. Pittsburgh Plastics Manufacturing provides this memory IsoFoam® in both low and high-density formulations and in open-cell structures to provide optimum breathability.

A flexible polyurethane foam that provides the ultimate pressure support and protection where you need it most. The molecular structure provides shock absorption, flexibility, elasticity and comfort by optimizing the achievable stress and tensile properties within foam.

PU IsoFoam® has mainly open cells, formed by gas bubbles that have popped. Air can pass through the foam easily, resulting in a soft, resilient, flexible material. Pittsburgh Plastic Manufacturing’s PU IsoFoam® is a cross-linked system that maintains its integrity while being stretched or compressed in any direction. IsoFoam® can support a large amount of weight (load) and remain soft and flexible over a long period of time. The unique cross-link structure provides high elasticity with high tensile strength.

Its exceptional soft cushioning properties allow for shear force reduction to the user’s skin and body.

Insulating IsoFoam®: Through optimizing cell structure and material density, Pittsburgh Plastics Manufacturing is able to provide insulating IsoFoam® for products that require thermal isolation.

Vibration and Impact Dampening IsoFoam®: The rebound and resiliency properties are key factors in reducing vibration and impact effects from a source. Vibration and impact dampening IsoFoam® can practically eliminate all transferred impact forces and vibratory waves.

Integral Skin IsoFoam®: Exhibits an outer “skin” layer that is flexible but feels more like plastic or simulated leather. This type of IsoFoam® allows for use as an all-in-one system of covering and foam interior. The skin of the foam can be used as the surface material and withstand all of the wear and tear of daily use. Examples for this type of PU IsoFoam® would be for chairs, floor mats, or head rests.

THE IsoFoam® ADVANTAGE:

Excellent Heat Resistance

Wide Range of Softnesses

High Tensile Strength

Wide Range of Densities

High Elongation

Fire Resistance

Excellent Compression Performance

Excellent Pressure Point Management

Chemical Resistance

Shock Absorbing

UV Resistance

Excellent Durability

Additional

IsoFoam® Formulations

Launch a New Product!

Do you have a great idea? We enjoy helping our partners bring their new products to life. Or helping them to refine and improve their existing product lines. Our experienced team of engineers provides you with support and advice throughout each step of the process.

From initial samples to prototyping and production-quality molds, our team is here to work with you and ensure you will deliver the highest quality product for your customers.