Polyurethane (PU) IsoGel®

A visco-elastic polyurethane material with 3-axis liquid-like deformation that helps absorb pressure while having memory properties like that of a solid in order to rebound to its original shape and provide support where needed.

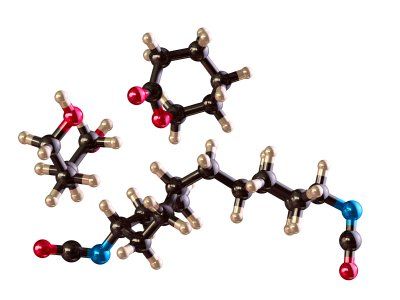

Pittsburgh Plastics Manufacturing’s PU IsoGel® is a cross-linked system that maintains its shape while being stretched or compressed in any direction. The molecular structure provides shock absorption through a fluid-like slip of the cross-link chains; however as the chains are long and dispersed through the material, IsoGel® can support a large amount of weight (load) without bottoming out. The unique cross-link structure provides high elasticity with high tensile strength.

The fluid-like properties also allow for even weight distribution and vibration dampening. Even though the gel has properties like that of a fluid, it will not leak or run. Its exceptional soft cushioning properties allow for shear force reduction to the user’s skin and body.

PU IsoGel® polymer has been tested and confirmed as stable, non-toxic, and non-irritating according to ISO 10993 biocompatibility tests parts 5, 10, 11, and 12. PU IsoGel® does not include Latex, Silicone, or Plasticizers.

The polyurethane IsoGel® system provides high thermal stability with its low thermal conductivity by acting like an insulator. Similarly, IsoGel® is electrically non-conductive, x-ray translucent, and appropriate for use in operating rooms and magnetic resonance imaging (MRI) machines. The unique chemical stability of this IsoGel® will not harden over time and is resistant to oils and greases.

PU IsoGel® can be molded into various shapes or be used as gel filler inside of cushions. It can be manufactured to a wide scale of durometers from the Shore A scale to below the Shore OOO range and into cone penetration levels. PU IsoGel® can be customized to almost any color including but not limited to clear, white, black, blue, red, yellow, and even glow in the dark!

*Note: color availability is product dependent

Multiple additives and formulations of the base polyurethane IsoGel® system allow for the following variations of the IsoGel® product:

- SSCP (Super Soft Cone Penetration) IsoGel®: Cone Penetration depth of 200 mm to 10 “OOO” durometer

- UHR (Ultra High Resiliency) IsoGel®: 10 “OOO” to 80 “OO” durometer

- ULR (Ultra Low Resiliency) IsoGel®: 10 “OOO” to 80 “OO” durometer

THE IsoGel® ADVANTAGE:

Conforms to body for superior cushioning

Does not support bacterial growth

Reduces skin shear and pressure

X-Ray & MRI translucent

Can reduce occurrences of pressure sores

Excellent shock absorption

High elasticity and tensile strength

Will not harden over time

Holds weight without bottoming out

High load bearing capability

Vibration dampening

Can be molded into any shape or form

Will retain its shape over time

Easily cleaned and sanitized

Won't absorb odors or fluids

Can be insulative or conductive

Extremely durable

Will never leak or break if punctured

Additional IsoGel® Formulations

Launch a New Product!

Do you have a great idea? We enjoy helping our partners bring their new products to life. Or helping them to refine and improve their existing product lines. Our experienced team of engineers provides you with support and advice throughout each step of the process.

From initial samples to prototyping and production-quality molds, our team is here to work with you and ensure you will deliver the highest quality product for your customers.